Equipment Used In Mass Vaccine Production

Brand GREAT ELITES

Product origin CHINA

Delivery time 6 month

Supply capacity 50 sets per year

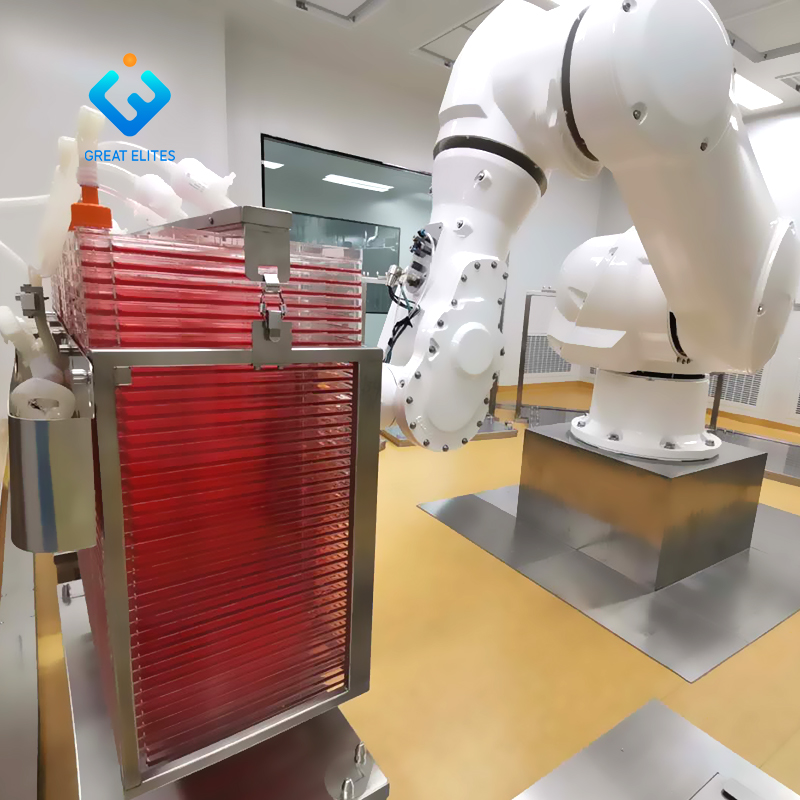

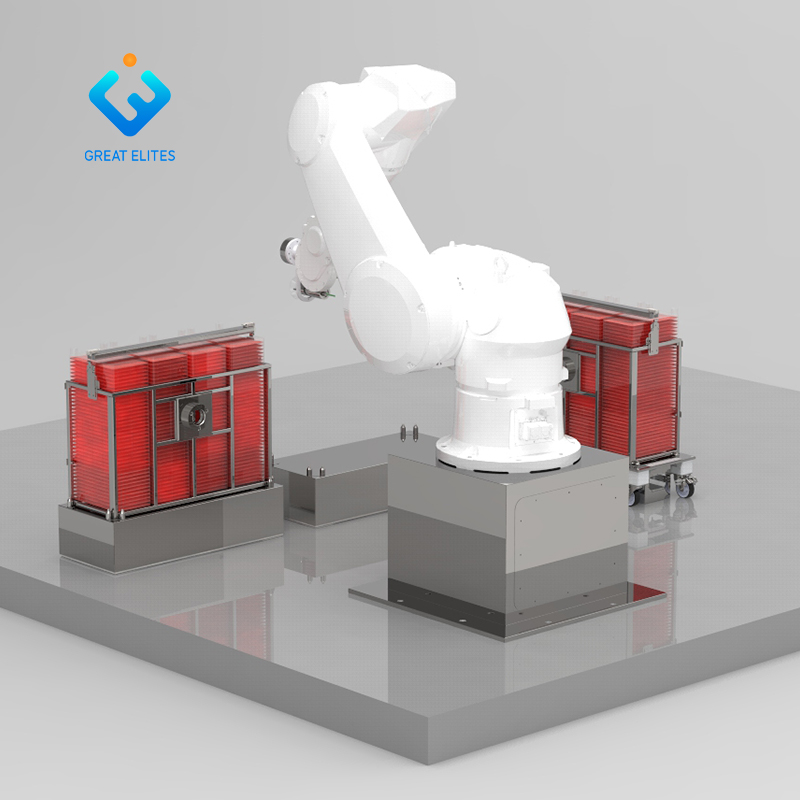

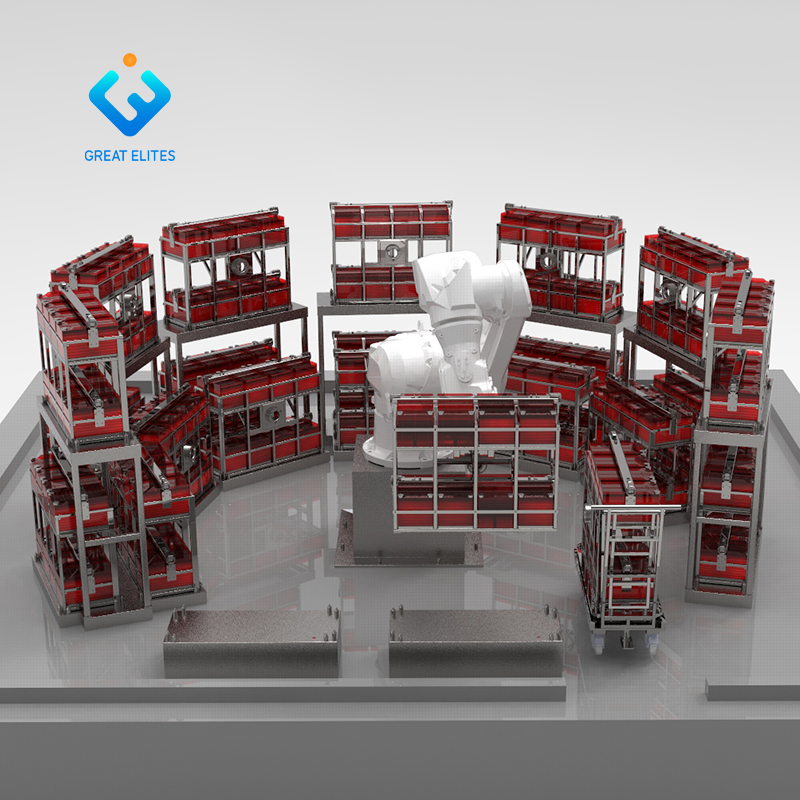

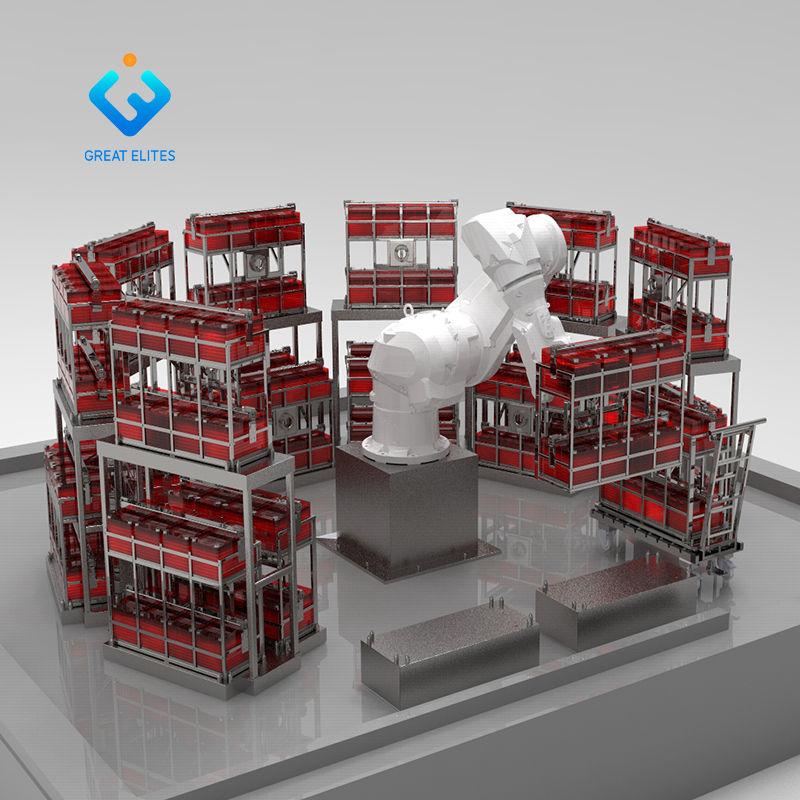

A large number of vaccine cell culture equipment, using sterile robots, can carry out the culture process operation of four groups of 40 layer cell factories at one time, which saves a lot of manpower and greatly improves the production capacity. At the same time, the consistency of robot operation ensures that the product quality has been stable, and the equipment meets the GMP class a cleanliness level.

The introduction of equipment used in mass vaccine production

A large number of vaccine cell culture equipment, using sterile robots, can carry out the culture process operation of four groups of 40 layer cell factories at one time, which saves a lot of manpower and greatly improves the production capacity. At the same time, the consistency of robot operation ensures that the product quality has been stable, and the equipment meets the GMP class a cleanliness level.

The characteristics of equipment used in mass vaccine production

Flexible application

Flexible operation, all action parameters (angle, speed, frequency, etc.) can be adjusted, and the development potential is unlimited.

Easy to operate

Highly integrated control system, no component handling, greatly reducing the labor intensity of operators.

Wide application range

The robot meets the use standard of class a environment, withstands VHP sterilization and breaks through the use limit of traditional equipment.

Strong compatibility

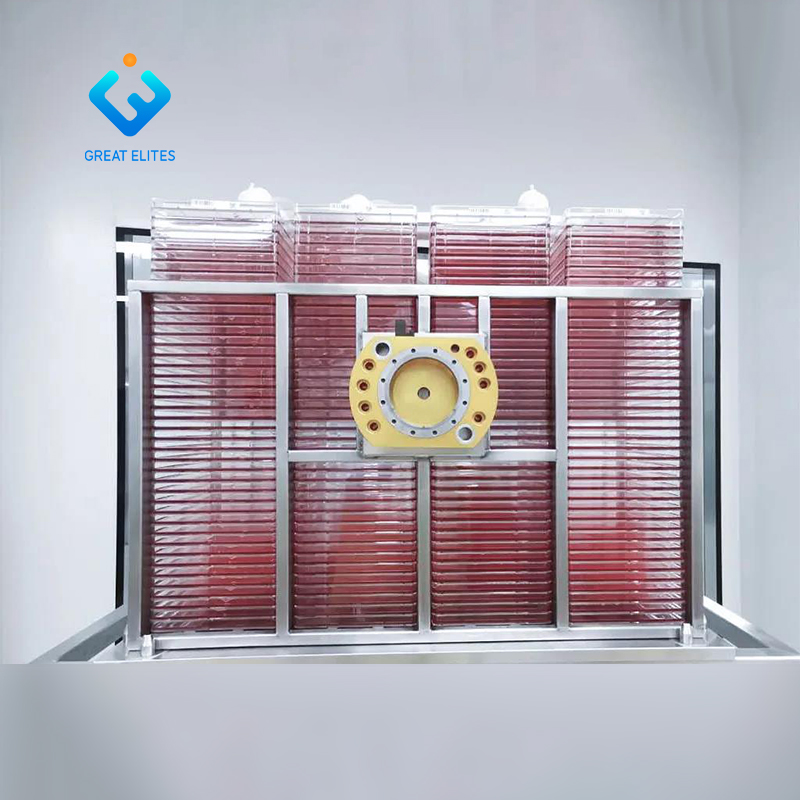

It can realize the compatibility of multi-layer cell culture systems of various brands.

Powerful endurance

Can meet 24 hours × Work continuously for 7 days.

High safety

Grating protection system can effectively protect the safety of operators and equipment.

Easy maintenance

Food grade liquid lubricating oil, with a replacement cycle of up to 20000 hours (continuous working hours)

Wide scalability

Modular operation platform, flexible for different application scenarios

Data management

Meet the management requirements of GMP / GLP regulations

Collect and record the production process and operation information data in real time, ensure the data traceability of products, and manage user rights

Operation records, machine status, alarm information and other data can be recorded

Seamless connection with SCADA, MES and other systems. Product features:

Flexible application

Flexible operation, all action parameters (angle, speed, frequency, etc.) can be adjusted, and the development potential is unlimited.

Easy to operate

Highly integrated control system, no component handling, greatly reducing the labor intensity of operators.

Wide application range

The robot meets the use standard of class a environment, withstands VHP sterilization and breaks through the use limit of traditional equipment.

Strong compatibility

It can realize the compatibility of multi-layer cell culture systems of various brands.

Powerful endurance

Can meet 24 hours × Work continuously for 7 days.

High safety

Grating protection system can effectively protect the safety of operators and equipment.

Easy maintenance

Food grade liquid lubricating oil, with a replacement cycle of up to 20000 hours (continuous working hours)

Wide scalability

Modular operation platform, flexible for different application scenarios

Data management

Meet the management requirements of GMP / GLP regulations

Collect and record the production process and operation information data in real time, ensure the data traceability of products, and manage user rights

Operation records, machine status, alarm information and other data can be recorded

The equipment used in mass vaccine production can be seamlessly connected with SCADA, MES and other systems